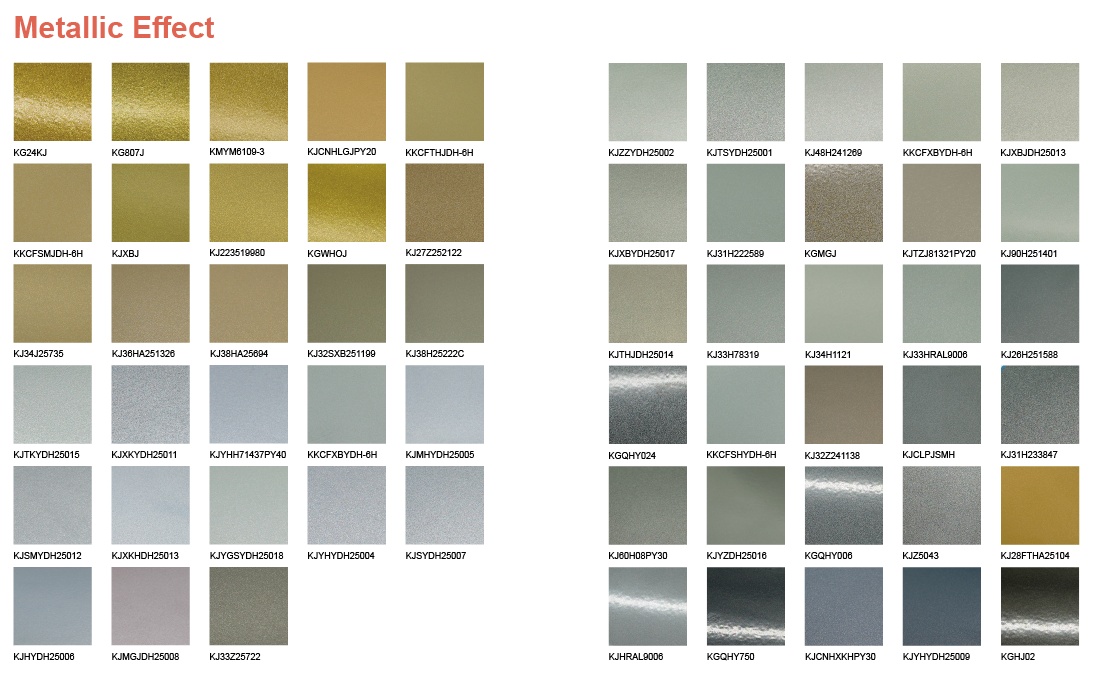

Metallic effect powder coating is a type of powder coating that contains metal powders (such as aluminum powder, copper powder, etc.). It is produced by blending metal powders with resin systems, pigments, curing agents, and other raw materials to form a coating with metallic luster, reflective effects, and unique texture, which can impart a visual effect resembling a metallic surface to objects. Our metallic effect powder coatings offer a wide range of color and gloss options and can be customized according to customer requirements.

With the growing demand for surface decorative effects in modern industry and home furnishing, powder coatings have gradually become one of the leading products in the coatings industry due to their environmental friendliness, high efficiency, and durability. Among them, metallic effect powder coating is a type containing metal powders (such as aluminum powder, copper powder, etc.). It is produced by blending metal powders with resin systems, pigments, curing agents, and other raw materials to form a coating with metallic luster, reflective effects, and unique texture. This coating is commonly applied on various metal surfaces to achieve a visual effect resembling that of a metallic finish.

Among the various types of powder coatings, metallic effect powder coatings have gained widespread application across multiple industries due to their distinctive visual appeal, excellent physical properties, outstanding corrosion resistance, wear resistance, UV resistance, and environmental advantages. They are now widely used in home appliances, architectural decoration, automotive and transportation, furniture and home decor, industrial equipment and components, as well as outdoor decorations and gardening products. Our metallic effect powder coatings offer a wide range of color and gloss options and can be customized according to customer requirements.

Detailed Information

Item No. | Test Item | Test Method | Test Result |

01 | Film Thickness | KETT Electromagnetic Thickness Gauge | 60-80μm |

02 | Storage Stability | Storage at 40°C for 3 weeks | No caking |

03 | Particle Size Analysis | MALVERN 2600 Particle Size Analyzer | D[V,0.5]: 36-40μm |

04 | Color Difference | Datacolor Colorimeter | ΔE < 0.5 |

05 | Pencil Hardness | Pencil Hardness Tester | 1H |

06 | Impact Resistance | ERICHSEN Testing Machine | 50 kg·cm |

07 | Adhesion | Cross-cut Test 1mm×100 | 100% |

08 | Application Method | Electrostatic Spraying | |

09 | Curing Condition | 200℃×10mins (Substrate Temperature) | |

10 | Appearance | Powder | |

11 | Color and Gloss | Customizable, suitable for all colors and gloss. | |

12 | Coverage(@60μm) | 9-12m2/kg | |

13 | Specific Gravity | 1.2-1.7g/cm3 up to colors | |

14 | Shelf Life | 12 months at dry ventilation conditions below 25℃ | |

15 | Certification | RoHS、REACH、ISO9001 | |

1. Superior Decorative Qualities

Luxurious Appearance: Can replicate various metallic finishes (such as stainless steel, aluminum, copper, brass) and high-end aesthetics, significantly enhancing product grade.

Diverse Effects: Offers a wide range of special visual effects including metallic luster, sparkle, hammer tone, brushed, and anodized looks to meet diverse design needs.

Color & Gloss: Provides extensive color and gloss options (high-gloss, semi-gloss, matte), enabling high design flexibility.

2. Excellent Durability and Protection

Outstanding Weather Resistance: Effectively resists UV rays, rain, and climatic changes, with minimal chalking or fading, ensuring long-lasting beauty.

Strong Corrosion Resistance: Offers excellent rust prevention and chemical corrosion protection for substrates, especially metals.

Exceptional Mechanical Properties: The coating is hard, with excellent abrasion, scratch, and impact resistance, ensuring long-term durability.

3. Environmental and Economic Benefits

Eco-Friendly: Solvent-free, near-zero VOC emissions, harmless to the environment and operator health.

Cost-Effective and Efficient: High transfer efficiency during application, overspray can be recycled, and typically a single-coat application reduces labor and material costs.

4. Broad Application Adaptability

Versatile Substrates: Primarily used on metals, but can also be applied to non-metals like MDF (Medium-Density Fiberboard) with special processes.

Cross-Industry Applicability: Suitable for a wide range of sectors including home appliances, architecture, automotive, furniture, electronics, and industrial equipment.

Classification | Type | Typical Applications |

By Metallic Pigment & Effect | Standard Metallic | Appliance housings (AC units, washing machines), lighting fixtures, metal furniture, general hardware. |

Sparkle / Glitter Metallic | High-end electronic housings, sports equipment, automotive wheels, artistic decorations. | |

Textured Metallic | Industrial equipment enclosures, professional tools, security doors, retro-style furniture. | |

Anodized Look-Alike | Consumer electronics (phone frames, laptop cases), architectural aluminum profiles, high-end display stands. | |

By Resin System | Epoxy / Hybrid | Indoor furniture, electrical enclosures, internal electronic components. |

Polyester | Architectural aluminum panels, windows/doors, outdoor railings, AC outdoor units, automotive trim. | |

Polyurethane | High-end furniture, automotive wheels, engineering machinery for demanding applications. | |

By Gloss Level | High Gloss | Home appliances, automotive parts, decorative items. |

Satin / Semi-Gloss | Office furniture, general industrial products, windows/doors. | |

Matte | High-end custom furniture, architectural profiles, industrial equipment. |

25 kgs/box, dry ventilation conditions below 25℃.

Feel free to contact us for customized products‘ specification and package

Contact: Bruce Wang

Phone: +86 13951823978

Tel: +86 025-58895705

Whatsapp: +86 13951823978

Email: bruce@aabindustrygroup.com

Add: No. 614, Building 01, Hongyang times business center, Jiangbei national New District, Nanjing, Jiangsu Province 210000

We chat