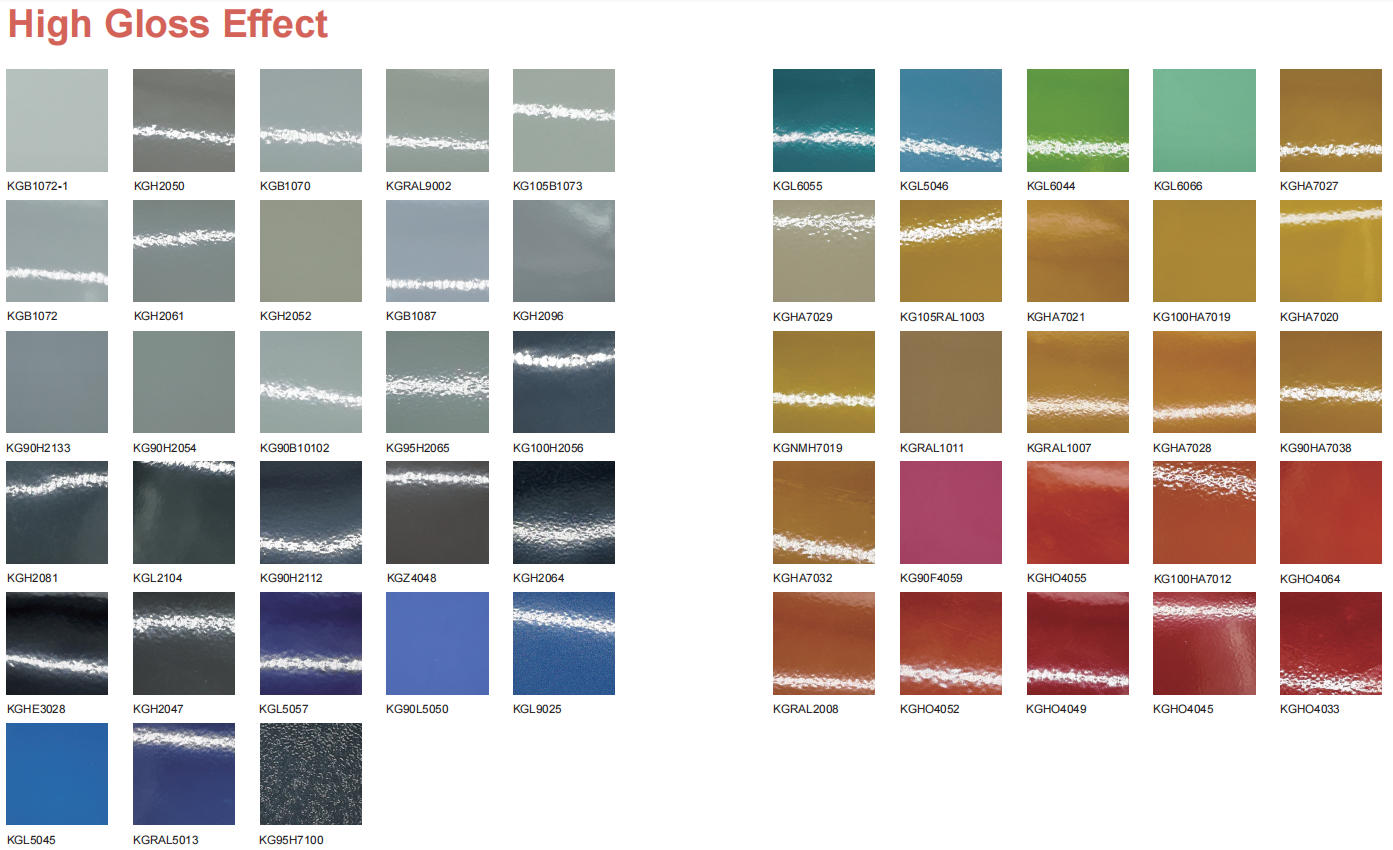

AAB Group‘s high-gloss powder coating is an environmentally friendly finishing material in solid powder form, capable of forming a bright, smooth, and nearly mirror-like high-gloss coating on metal surfaces. It is valued not only for its excellent decorative appeal but also for its outstanding durability, making it widely used in a variety of fields such as home appliances, automotive parts, architectural hardware, electronic product casings, modern furniture, and industrial equipment. Our high-gloss powder coatings are available in various colors and can also be customized in texture according to customer requirements.

High-gloss powder coating is an environmentally friendly finishing material in solid powder form, capable of forming a bright, smooth, and nearly mirror-like high-gloss coating on metal surfaces. It is valued not only for its excellent decorative appeal but also for its outstanding durability, making it widely used in a variety of fields such as home appliances, automotive parts, architectural hardware, electronic product casings, modern furniture, and industrial equipment.

Once cured, the coating exhibits multiple superior properties: high hardness, scratch resistance, corrosion resistance, UV resistance, and strong weatherability. These ensure that products maintain both a vibrant appearance and structural stability over long-term use. Moreover, the material is solvent-free and low in pollution, with the coating process generating almost no volatile organic compounds (VOCs), meeting today’s stringent requirements for green and sustainable manufacturing.

In terms of application, high-gloss powder coating offers high material utilization and excellent leveling performance, contributing to improved coating efficiency and reduced material waste. Although it demands higher standards for substrate pretreatment and application techniques and comes at a relatively higher cost compared to conventional powder coatings, it excels in high-end applications where aesthetics and durability are critical. It has thus become an important direction in modern coating technology. Our high-gloss powder coatings are available in various colors and can also be customized in texture according to customer requirements.

Item No. | Test Item | Test Method | Test Result |

01 | Film Thickness | KETT Electromagnetic Thickness Gauge | 60-80μm |

02 | Storage Stability | Storage at 40°C for 3 weeks | No caking |

03 | Particle Size Analysis | MALVERN 2600 Particle Size Analyzer | D[V,0.5]: 36-40μm |

04 | Color Difference | Datacolor Colorimeter | ΔE < 0.5 |

05 | Pencil Hardness | Pencil Hardness Tester | 1H |

06 | Impact Resistance | ERICHSEN Testing Machine | 50 kg·cm |

07 | Adhesion | Cross-cut Test 1mm×100 | 100% |

08 | Application Method | Electrostatic Spraying | |

09 | Curing Condition | 200℃×10mins (Substrate Temperature) | |

10 | Appearance | Powder | |

11 | Color and Gloss | Customizable, suitable for all colors. | |

12 | Coverage(@60μm) | 9-12m2/kg | |

13 | Specific Gravity | 1.2-1.7g/cm3 up to colors | |

14 | Shelf Life | 12 months at dry ventilation conditions below 25℃ | |

15 | Certification | RoHS、REACH、ISO9001 | |

1. Superior Decorative Appeal and Visual Excellence

Mirror-like high-gloss finish: The coating surface is smooth and bright, achieving a near-mirror high gloss (typically above 85 GU), giving products a premium, refined, and modern visual texture.

Rich and vibrant color performance: Colors are vibrant, pure, and highly stable, meeting diverse design needs and significantly enhancing the product’s appearance and brand recognition.

Excellent leveling properties: After application, the coating self-levels to form a smooth, orange-peel-free, and particle-free perfect surface.

2. Outstanding Physical and Chemical Performance

Exceptional durability: The coating offers high hardness (up to 2H or higher) and excellent scratch resistance, effectively resisting daily wear and tear.

Superior weather and UV resistance: Even with long-term outdoor exposure to sunlight, rain, and wind, it maintains gloss and color retention, resists yellowing or chalking, and ensures a long service life.

Strong corrosion resistance: Provides excellent resistance to common chemicals, solvents, oils, and humid environments, with outstanding salt spray test performance, making it suitable for harsh conditions.

3. Environmental and Health Safety

100% solid content, zero VOC emissions: Contains no harmful solvents during production and application, generating almost no volatile organic compounds. It is safe for operators and complies with the world’s strictest environmental regulations (e.g., REACH, RoHS).

High material utilization: Oversprayed powder can be recycled and reused, with utilization rates typically exceeding 95%, significantly reducing waste and overall costs.

Free of heavy metals: The formulation contains no harmful heavy metals such as lead or chromium, ensuring safety and environmental friendliness.

4. Efficient Application and Economic Benefits

High coating efficiency: A single application achieves the desired thickness, with fast leveling and curing, saving time and energy.

Excellent cost-effectiveness: While the material cost may be slightly higher than conventional coatings, its high utilization rate, low rejection rate, no need for environmental treatment costs, and reduced maintenance expenses due to long lifespan make it more competitive in total lifecycle cost.

Broad process adaptability: Suitable for various metal substrates (e.g., aluminum, steel, magnesium alloys) and customizable in color and texture to meet personalized design requirements.

Classification | Specific Category | Key Characteristics | Typical Application Areas |

By Resin System | Epoxy High-Gloss Powder Coatings | Excellent adhesion, high hardness, strong chemical resistance, limited weatherability (prone to chalking/yellowing) | Indoor environments: Filing cabinets, chassis housings, shelving, hardware tools, laboratory equipment |

Polyester High-Gloss Powder Coatings | Balanced overall performance, excellent weatherability and UV resistance, good decorative appeal | Outdoor/durable environments: AC outdoor units, outdoor lighting fixtures, fencing, automotive aluminum wheels, garden furniture | |

Epoxy-Polyester Hybrid | Cost-effective, good leveling, mechanical and chemical resistance between epoxy and polyester | General-purpose: Household appliance housings (e.g., washing machine panels), office furniture, radiators, general metal products | |

Acrylic High-Gloss Powder Coatings | Very high gloss and fullness, excellent weatherability and gloss retention, stain-resistant | High-end decoration: Premium appliance panels (e.g., refrigerators), automotive exterior trim, motorcycle components | |

Fluorocarbon High-Gloss Powder Coatings | Super-weatherable (up to 20+ years), exceptional corrosion resistance and self-cleaning properties, high cost | Demanding outdoor/landmark architecture: Premium architectural aluminum curtain walls, airport facilities, cross-sea bridge components | |

By Functional Property | Antibacterial High-Gloss Powder Coatings | Contains antibacterial agents (e.g., silver ions), provides lasting antibacterial and anti-mold functions | Hygiene-sensitive settings: Medical equipment housings, kitchen appliances, school/hospital furniture, food processing equipment |

Conductive High-Gloss Powder Coatings | Provides electromagnetic interference (EMI) shielding or electrostatic discharge (ESD) dissipation | Electronics & Electrical: Server cabinets, electronic instrument enclosures, communication base station shielding covers | |

High-Temperature Resistant High-Gloss Powder Coatings | Withstands long-term temperatures above 200°C while maintaining gloss and adhesion | High-temperature environments: BBQ grills, heaters, engine components, lighting fixtures (especially LED heat sinks) | |

Scratch & Abrasion Resistant High-Gloss Powder Coatings | Extremely high surface hardness (up to 3H or more), excellent scratch resistance | High-wear scenarios: High-speed rail/subway interior panels, luggage shells, fitness equipment, frequently used tool panels | |

By Surface Effect | Solid Color High-Gloss | Full, even color, achieving a perfect mirror-like finish | Widely used in all fields requiring a bright appearance; the base effect |

Metallic Effect High-Gloss | Contains aluminum or bronze flakes, presents a metallic shimmer with high gloss | Premium appliance handles, trim strips, lighting fixtures, musical instruments, bathroom hardware | |

Pearlescent/Color-Shift Effect High-Gloss | Contains pearl pigments, presents soft pearlescence or angle-dependent color effects | Cosmetic packaging, high-end electronics housings, artistic decorations, motorcycle helmets | |

Clear/High-Gloss Topcoat | High transparency, used as a protective, brightening layer over plated, etched, or colored surfaces | Protective topcoat for signage, metal logos, premium faucets | |

By Gloss Level | Super High-Gloss | Gloss ≥ 95 GU, achieving a mirror-like effect, requires extremely high substrate smoothness and process control | Luxury packaging boxes, high-end decorative parts, display models, premium cosmetic containers |

Standard High-Gloss | Gloss 80-95 GU, bright and smooth, the most common high-gloss standard | Appearance parts for the vast majority of appliances, automotive components, general industrial goods | |

Soft High-Gloss/Satin Gloss | Gloss 60-80 GU, soft reflection, reduces glare, smooth tactile feel | Laptop housings, high-end office equipment, medical device control panels, automotive interior trim |

25 kg/box, dry ventilation conditions below 25℃.

Feel free to contact us for customized products' specification and package

Contact: Bruce Wang

Phone: +86 13951823978

Tel: +86 025-58895705

Whatsapp: +86 13951823978

Email: bruce@aabindustrygroup.com

Add: No. 614, Building 01, Hongyang times business center, Jiangbei national New District, Nanjing, Jiangsu Province 210000

We chat