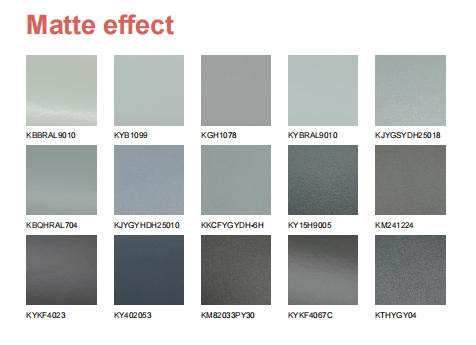

AAB Group‘s matte powder coatings offer excellent weatherability, UV resistance, corrosion resistance, anti-fouling properties, and scratch resistance. They are widely applied across multiple fields including household appliances, automotive, construction, furniture, medical, and military sectors. Our matte powder coatings provide a rich selection of colors, combining multi-level gloss and diverse textural effects, and can be customized according to customer requirements.

Matte powder coatings are a type of coating characterized by their unique low-gloss appearance. In materials engineering, they are classified as flat or matte coatings, typically featuring a pigment volume concentration above 45% and a film gloss level below 30%. Their low-gloss characteristics originate from factors such as higher surface roughness of the coating film, uneven pigment particle distribution, and imbalance during solvent evaporation. The resulting surface exhibits a soft and subdued visual effect.

Similar to other types of powder coatings, matte powder coatings are primarily composed of resins, curing agents, pigments, fillers, and various additives. During production, the coating is applied evenly to the substrate through electrostatic spraying and then cured by heating to form a strong, continuous film.To achieve the matte effect, appropriate amounts of matting agents (such as fluororesins and silicates), along with aluminum stearate and wax-based matting additives, are incorporated during formulation. In 2018, the industry developed high-wear-resistant and recoatable UV-curable matte coatings, formulated with prepolymers and matting waxes. By precisely controlling the proportion of these additives, the gloss level of the coating can be finely adjusted to meet different application requirements. As a result, matte powder coatings can deliver the desired visual appearance without compromising other essential performance properties.

Compared with traditional liquid coatings, powder coatings contain no solvents, and therefore do not release harmful volatile organic compounds (VOCs) during application, providing a significant environmental advantage. This makes them an increasingly preferred choice in a market with rising environmental awareness.

Thanks to their distinctive aesthetic qualities, outstanding durability, and environmentally friendly characteristics, matte powder coatings have become increasingly popular in today’s coating market. They not only meet consumer demands for beauty, durability, and sustainability but also provide excellent weather resistance, UV resistance, corrosion resistance, stain resistance, and scratch resistance. They are widely used in home appliances, automobiles, architecture, furniture, and many other sectors. Semi-gloss coatings are particularly suitable for indoor environments requiring soft lighting—such as hospitals and hotels—while full matte coatings are used in military equipment to enhance camouflage performance.

With continuous technological advancements, the application potential and market space for matte powder coatings are expected to expand further, making them an important development trend in the coating industry.

Item No. | Test Item | Test Method | Test Result |

01 | Film Thickness | KETT Electromagnetic Thickness Gauge | 60-80μm |

02 | Storage Stability | Storage at 40°C for 3 weeks | No caking |

03 | Particle Size Analysis | MALVERN 2600 Particle Size Analyzer | D[V,0.5]: 36-40μm |

04 | Color Difference | Datacolor Colorimeter | ΔE < 0.5 |

05 | Pencil Hardness | Pencil Hardness Tester | 1H |

06 | Impact Resistance | ERICHSEN Testing Machine | 50 kg·cm |

07 | Adhesion | Cross-cut Test 1mm×100 | 100% |

08 | Application Method | Electrostatic Spraying | |

09 | Curing Condition | 200℃×10mins (Substrate Temperature) | |

10 | Appearance | Powder | |

11 | Color and Gloss | Customizable, suitable for all colors and gloss. | |

12 | Coverage(@60μm) | 9-12m2/kg | |

13 | Specific Gravity | 1.2-1.7g/cm3 up to colors | |

14 | Shelf Life | 12 months at dry ventilation conditions below 30℃ | |

15 | Certification | RoHS、REACH、ISO9001 | |

1.Outstanding Matte Visual Effect

Utilizing advanced matting technology and precise formulation control, our coatings deliver a delicate, soft, and non-reflective matte finish. The surface exudes a premium texture, providing a subtle and elegant visual appeal.

2.Excellent Weather and UV Resistance

Our matte coatings offer superior outdoor durability, maintaining stability under prolonged exposure to sunlight, rain, and temperature fluctuations. They resist fading and gloss loss, making them ideal for outdoor equipment and architectural applications.

3.High Wear, Scratch, and Stain Resistance

With carefully selected resin systems and enhanced additives, the coatings provide exceptional mechanical strength, effectively resisting scratches, stains, and everyday wear, keeping surfaces looking new for longer.

4.Environmentally Friendly, VOC-Free

Our coatings are completely solvent-free, containing no volatile organic compounds (VOCs), fully compliant with current environmental regulations, and representing a safe and sustainable coating solution.

5.Superior Adhesion and Corrosion Resistance

The dense, robust coating structure effectively isolates moisture, oxygen, and corrosive substances, significantly enhancing substrate corrosion resistance and extending service life—particularly suitable for metal products and outdoor equipment.

6.Wide Range of Applications

Our matte powder coatings are widely used in home appliances, automotive components, building materials, furniture, electronics, machinery, and military equipment, meeting both decorative and protective requirements.

7.Customizable Gloss and Performance

We can precisely adjust gloss levels (semi-matte, low-gloss, full-matte), colors, weathering resistance, and mechanical properties according to customer needs, offering flexible and tailored solutions.

8.Efficient Application and High Utilization

Powder coatings ensure high spraying efficiency, excellent transfer and recovery rates, uniform coatings without sagging, and fast curing, helping reduce production costs and improve manufacturing efficiency.

Classification | Main Category | Core Characteristics | Typical Application Areas |

By Resin System | Epoxy Matte | High hardness, strong adhesion, good chemical corrosion resistance, cost-effective; but prone to chalking and poor weatherability. | Indoor Environments: Cabinets, file cabinets, hardware tools, electronic component housings, indoor pipes, automotive interior functional parts. |

Polyester/TGIC (or HAA) Matte | Excellent weatherability, UV resistance, good mechanical properties, and heat resistance; strong outdoor durability. | Outdoor Environments: Door and window profiles, curtain wall aluminum panels, fences, outdoor lighting fixtures, automotive exterior parts (e.g., wheels, bumpers), construction machinery. | |

Polyurethane Matte | Exceptional weatherability, wear resistance, impact resistance, and high decorative quality; superior comprehensive performance; higher cost. | High-end and Harsh Environments: Premium automotive wheels, motorcycle frames, outdoor signage, agricultural machinery, high-demand architectural components. | |

Acrylic Matte | Excellent gloss and color retention, stain resistance, high transparency and hardness, outstanding weatherability. | High-Decoration and High-Weathering Fields: Premium metal decorative panels, household appliance panels (e.g., air conditioners), outdoor products requiring high durability. | |

Fluorocarbon Matte | Top-tier weatherability and self-cleaning properties, extreme environment color and gloss retention (20+ years), excellent chemical resistance and anti-fouling properties; highest cost. | Ultra-long Durability and High-end Decorative Fields: Super high-rise building curtain walls (landmark buildings), airport/station large-scale roofs, coastal or heavy industrial pollution zone facilities, permanent engineering with minimal cleaning and maintenance requirements. | |

Hybrid (Epoxy-Polyester) Matte | High cost-effectiveness, balanced weatherability and mechanical properties, versatile. | General-purpose Indoor/Outdoor Products: Office furniture, shelves, radiators, general industrial equipment, light outdoor facilities. | |

By Gloss Level and Appearance | Full Matte/Ultra Matte (Gloss ≤ 15°) | Extremely understated, heavy texture, completely non-glossy, effectively hides minor surface defects, fine touch. | Fields with Strict Anti-glare Requirements: Professional photographic equipment, optical instrument housings, high-end audio equipment, museum display cases, military equipment. |

Semi-Matte/Soft Matte (Gloss 15° - 50°) | Soft gloss, premium texture, most widely used, balances aesthetics and stain resistance. | Mainstream Consumer and Industrial Fields: Household appliances (refrigerators, washing machines), IT equipment (laptops, routers), furniture, lighting fixtures, general industrial goods. | |

Special Effect Matte | Superimposes special texture or feel on a matte base. | - Sandy/Wrinkled Matte: Toolboxes, fitness equipment, security doors; can conceal substrate defects. | |

By Additional Functionality | Functional Matte | Provides matte appearance while imparting special functionality to the coating. | - Antibacterial Matte: Medical equipment panels, kitchen appliances, public facilities. |

Package and Storage

25 kg/box, dry ventilation conditions below 30℃.

Feel free to contact us for customized products‘ specification and package

Contact: Bruce Wang

Phone: +86 13951823978

Tel: +86 025-58895705

Whatsapp: +86 13951823978

Email: bruce@aabindustrygroup.com

Add: No. 614, Building 01, Hongyang times business center, Jiangbei national New District, Nanjing, Jiangsu Province 210000

We chat